From the forest to the mill yard

Harvested timber is delivered from the nearby forest to the mill yard.

Call us 01709 838188 or Get in Touch

6-8 weeks current supply only lead time

10 year warranty, 60 year life expectancy

10-12 weeks current supply and installation lead time

Designed by you, made to measure by us

99.5% of our customers would recommend us

Double glazed whole window U-values as low as 1.3W/m²K

We are completely unique in that we have our own dedicated sawmill which supplies our factory with sawn, kiln dried and finger-jointed laminated sections for our wooden windows and doors.

Book A ConsultationHarvested timber is delivered from the nearby forest to the mill yard.

Logs are sorted by heartwood content, size and diameter ready for processing through the mill.

Bark is removed from the cut and sorted logs, and the correct width of boards are cut for each different window and door style we make.

Sawn timber is stacked in the yard ready for the kilns. Our sawmill operation has five kilns to dry the timber to a specific moisture content. Between 12% and 7% is the optimum moisture level we use for stability which is a necessity in structural timbers used for construction.

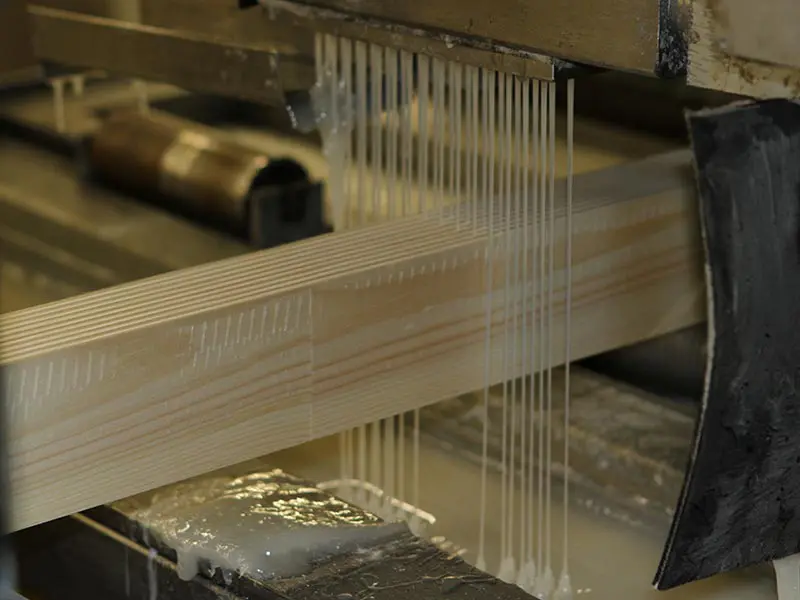

Once dried the timber enters the laminated timber line, or Glulam line, as they are often called. Here the timber is planed first of all to remove all rough edges.

Once planed, our trained timber operatives mark out sections on the wood to highlight defects such as knots and shakes. The machine then x-rays the surface of the planed timber looking for these highlighted lines and makes a cut where the line is creating defect free timber sections.

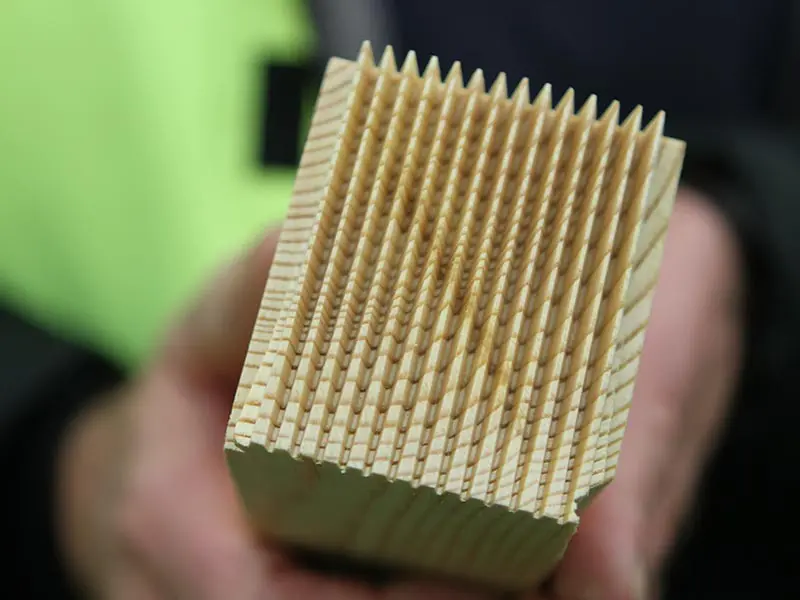

Now the knots and shakes have been eliminated, the sections that remain are finger jointed. Finger jointing is recognised as the most stable method of jointing together timber into lengths. It creates a incredibly strong bond between two sections of timber that is considered stronger than the timber itself, as a solid piece.

The finger jointed sections are then glued and closed together piece by piece under the pressure of a machine creating a perfect flush seam. Sections are then glued and laminated together for stability in three layers. The grain of the central layer runs in opposing direction of the outer layers.

Each completed finger jointed and laminated timber section is inspected for quality, removing anything that is not to standard. Finally the sections are packaged, labelled and prepped to be shipped into the factory for production to begin.

The key driver for the adoption of the sawmill into our supply chain was to improve our control of the timber section sizes. It is the norm for wooden window and door suppliers to use ready-made sections of laminated timber from sawmills to standard section sizes to make their windows and doors.

Additionally, in 2006 we saw unprecedented demand and an acute shortage of redwood pine laminated sections. As 90% of timber used in UK construction is redwood, these supply problems drastically extended the lead times of all wood-manufactured products. Not only did this cause a major inconvenience but also severe delays on site. As a result, we actively sought to reduce the risk going forward.

Having our own sawmill simply means we always have superior timber stock available in the right section sizes. It is designed especially for homes in the UK and meets the exceptional quality standards that we impose on ourselves.

The redwood raw material we use is either FSC® 100% certified or 100% PEFC certified. Our sawmill plant is also a certified manufacturer and supplier of laminated timber.

Wood waste that is generated in the production process of our timber windows and doors is transported by a silo system to a concrete silo with a capacity of 500 m3.

From here it is automatically collected by the fuel supply system to the boiler. Out of the heating season, surplus wood waste is briquetted for use in the furnaces and fireplaces of the local village.

Nothing goes to waste at Bereco. All of our timber windows and doors are delivered on FSC® 100% certified & 100% PEFC certified timber pallets which are made from the wood that comes from our forest and the offcuts from the sawmill. These pallets are then collected post-delivery, where possible, and reused for future deliveries – extending their service life before eventually being recycled.

Whether you’re a homeowner working on a renovation project for your home, an architect looking for specific windows and doors, or a trade professional building new homes and properties, we offer a tailored service to help you budget, design, and order bespoke timber windows and doors.

HomeownersProfessionalsWorking on a renovation, remodel, or self-build project? Let’s create your dream windows & doors together! Book a free design consultation, and we’ll help you find the style that best suits your home and budget — supporting you through the ordering process every step of the way.

Book a ConsultationRussell

Suiters

Liam

Helen

Jill

Nuro Design & Build

Carl

Nigel and Deborah

Alexandra

Chris

Scott

Scott

Conor

Peter

Peter

Samuel

Sign up to our mailing list and be kept up to date with our latest news, promotions and inspiration for your next project.